Sewon Q&TECH

제품소개

세계를 향한의지, 세원은 세계초일류 기업으로 세계를 경영해 나갑니다.

Injection & Sampling Quill

최고의 신뢰성 고품질을 추구하겠습니다.

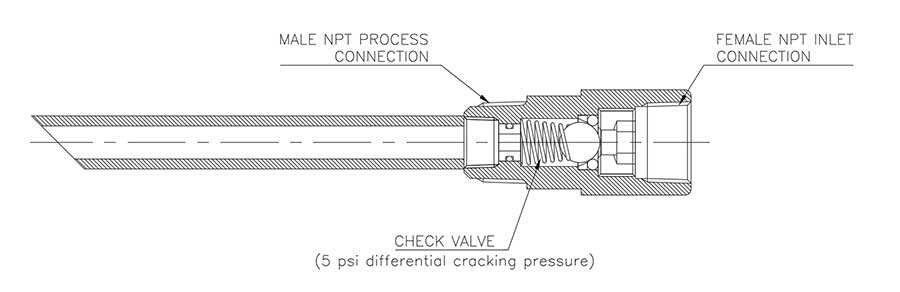

Fixed Injection Quills (code:QF)

SEWON Fixed Chemical injection quills ensure that chemicals are evenly dispersed into the center of the pipeline, which prevents channeling of the chemical down the pipe wall. The body and stinger are both constructed of chemical resistant materials (SUS 316L or Duplex Stainless steel). The Fixed quills are equip with a check valve with 5psi differential cracking pressure

Ordering Information (code:QF) – Fixed Injection Quills

| Check Valve | Ceramic Ball with with 5 PSI differential cracking pressure | |||

|---|---|---|---|---|

| Port Type | F | Flange RF SUS 316L, standard UNS S31603 NACE MR0175 | ||

| T | NPT male thread SUS 316L, standard UNS S31603 NACE MR0175 | |||

| X | Other materials are available upon request | |||

| Port Size | 012 | Flange RF 1/2” | 012 | NPT Thread 1/2” |

| 034 | Flange RF 3/4” | 034 | NPT Thread 3/4” | |

| 100 | Flange RF 1” | 100 | NPT Thread 1” | |

| 200 | Flange RF 2” | 200 | NPT Thread 2” | |

| 800 | Flange RF 8” | 212 | NPT Thread 2 1/2” | |

| XX | Other sizes are available upon request | |||

| Injection Tube | ||||

| Material | 316S | Stainless Steel s316L, bar UNS S31603 NACE MR0175 | ||

| 318S | Duplex ASTM A479, bar UNS S31803 NACE MR0175 | |||

| 105A | Carbon Steel ASTM A105 | |||

| 000X | Other materials are available upon request | |||

| Tube Size | T014 | Injection Tube 1/4” | ||

| T038 | Injection Tube 3/8” | |||

| T012 | Injection Tube 1/2” | |||

| TXXX | Other sizes are available upon request | |||

| Tube End Connection |

CF000 | Flange Connection (Ex) 3/8” Flange : CF038 | ||

| CT000 | NPT Thread Connection (Ex) 1/2” NPT thread : CT012 | |||

| Tube Stroke Length |

L15 | Tube Stroke Length 15” | ||

| L20 | Tube Stroke Length 20” | |||

| L25 | Tube Stroke Length 25” | |||

| LXX | Other sizes are available upon request | |||

| Stroke Length = Run pipe OD 1/2+ Fitting Height (h) | ||||

Example

[NOTES] The risk of damage to the solution tube when installed into flowing service increases with both solution tube length and process flow velocity. Consult with the factory for a maximum recommended insertion length for your process to avoid wake frequency problems in connection with resonance